Case Study

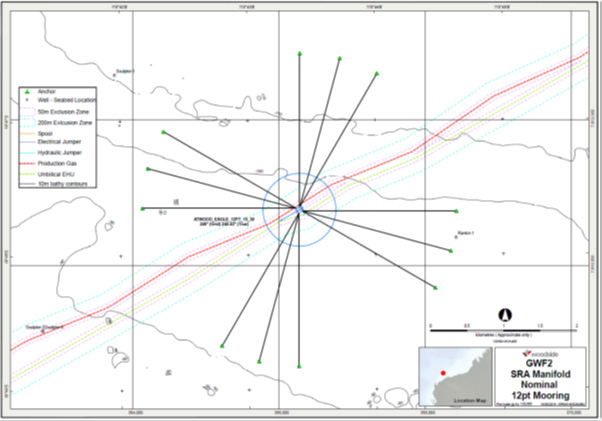

Fugro TSM Pty Ltd – GREATER WESTERN FLANK II – 12no Mooring Piles – Feb to July 2016

Fugro-TSM is a subsea contractor offering a range of services to the Oil and Gas Marine Industries. Operating globally they had a requirement from their Perth Australian Office for 12 off mooring piles for Woodside Petroleum – Greater Western Flank Project. Fugro’s scope of work was to design, fabricate and install the piles within a given time frame and budget.

Fugro approached Energy Services Steel Company amongst others to provide pricing for the piles and requested for various scenarios to be considered such as supply as single cans, complete piles, complete piles with internal stiffeners and guides etc.

Fugro had an issue that their design was not yet complete but they had a small window for installation due to oncoming typhoon season which if they failed to install on time would result in significant penalties on their company from Woodside Petroleum.

The challenges that were faced by ESS in bid process included:

-

- Design was not complete as geology was not entirely clear

- Very short lead time to manufacture to meet weather window

- Competition from Australian, Korean and Singaporean fabricators at low cost.

The solution we offered was to agree on the maximum outside diameter, thickness and length of the piles would be with a guide rate on final prices. After an extended period of negotiation, our company secured the order and with a planned delivery ahead of schedule and on budget that the client could work with.

The Korean alternative was considered by Fugro as they had a vessel in the area collection anchor chain but this was rejected as final fabrication and fit out would have to be done in Singapore, adding additional cost in loading and lead time.

The Singapore offer was rejected as they did not offer the freedom of the design to be changed and were limited to outsourcing any additional material requirements.

The Australian option was rejected as they were not competitive due to location, lead time to get raw material and availability of local supply in case of design change.

It was agreed that the pricing rate that we had proposed could be amended (downwards) by Fugro as their engineering detail was completed. We would then pre-order the plate from the plate mill and book the capacity with the pile rolling mill.

This significantly allowed an additional 10 weeks engineering time for Fugro as the plate was produced and delivered to Malaysia in advance of rolling schedule.

We offered proximity of local fabricators, our stock supply and the ability to direct load onto their vessel which they would moor at the adjacent Port to the mill at Tanjug Langsat (Malaysia). Overall these proposals offered attractive cost savings and incentives in price reduction and a compressed lead time which reduced risk. We also displayed a proven track record of previous supply to the same client and others in this sector.

The design changed considerably within this initial 10-week time frame but we had a backup of supplying material from our own stock that could be used for the ancillary requirements and thus design changes were accommodated with no impact on final delivery.

This was also positive benefit for our company as we released stock and the Clients design and schedule was maintained.

The project which was valued in excess of US$ 3 million on final review took six months to complete from the initial quotation to final load out with 100% acceptance on schedule, quality, final documentation and customer satisfaction.